Mighty Buildings delivers world’s first 3D printed zero net energy home

Paul Hanaphy October 13th 2022 0

Californian construction start-up Mighty Buildings has announced the delivery of the first 3D printed zero net energy home.

Assembled from a set of 3D printed prefab panels, the two-bed, two-bath home is set to be the first in a community of at least 40 housing units, at a site in Southern California. As well as completing the structure, which produces as much energy as it consumes, the firm has now unveiled plans to expand its B2B offering, as a means of delivering eco-friendly homes at a wider scale.

“We are proud to lead the shift to climate-friendly construction, and we encourage the industry to join us for the benefit of the planet and our society,” says Mighty Buildings COO Russ Atassi. “We are working directly with home developers to empower them with the technology to deliver bright, modern and sustainable homes at scale, and address the housing and climate crises head-on.”

“We believe we are just scratching the surface of what can be accomplished through robotics and 3D printing.”

Mighty Buildings’ first 3D printed net-zero energy home. Photo via Mighty Buildings.

Mighty Buildings’ prefab buildings

Although Mighty Buildings’ 3D printing technology has been under development since 2017, the firm itself didn’t leave stealth mode until two years ago. Since then, Mighty Buildings’ $100 million funding drive has provided it with the capital to continue building out its portfolio of Accessory Dwelling Units (ADUs), as well as scaling its production capabilities.

Said to be the first to gain UL 3401 safety certification, the firm’s technology revolves around a proprietary lightweight material and extrusion technique. The former is designed to harden almost immediately after post-curing, while still maintaining cohesion with its underlying layers, in a way that enables the creation of overhang structures like ceilings without supports.

Using this process, Mighty Buildings manufactures panels that can be slotted together to enable the rapid construction of housing, and it has already unveiled plans to 3D print a fifteen-strong neighborhood at a site near Coachella Valley.

In terms of sustainability, the company has long heralded the benefits of its technology in the creation of eco-friendly homes. Mighty Buildings has put its products through a full life cycle assessment (LCA) to ensure it has cut waste from every possible angle, and it has set itself the lofty goal of delivering carbon-negative construction by 2028.

The interior of Mighty Buildings’ first 3D printed net-zero energy home. Photo via Mighty Buildings.

Striving for housing sustainability

Mighty Buildings’ first in what’s set to be a whole community of zero net energy 3D printed homes, is designed to generate at least as much (if not more) energy than it uses. The build itself was constructed using the firm’s Mighty Kit System, which is essentially a set of prefab, insulated, steel frame-reinforced composite stone panels, that can be assembled by a few crew members into a full-blown building.

As these walls are made from 60% recycled material, Mighty Buildings says they require less material per square footage, and generate as much as 99% less waste than traditionally-built housing. The company also claims that using its ready-to-assemble kits, it’s possible to build homes in less than half the time, while helping minimize any reliance on potentially fragile construction supply chains.

Following the successful build of its first zero net energy home, Mighty Buildings has announced an expansion of its strategy to “focus on joint projects with developers.” In practice, the firm says this will see it grow its B2B operations to “empower housing developers to build communities of sustainable homes at scale.”

“We are excited to be the first company in the world to complete what we believe to be the sustainable housing standard in the future,” adds Mighty Buildings CEO Slava Solonitsyn. “The first 3D-printed ZNE home ever built is a result of years of R&D processes, including creation of a proprietary, certified construction technology and a revolutionary alternative to concrete which provides drastically lower thermal conductivity.”

“Housing developers will no longer have to choose between profitability, quality, design and protecting the planet.”

An Azure Printed Homes ‘Iris’ ADU 3D printed from recycled plastic. Image via Azure Printed Homes.

Material advances in construction AM

Traditionally, construction 3D printing involves depositing material from a giant nozzle layer-by-layer into structures, and the sustainability of this process largely revolves around what’s used as feedstock. Azure Printed Homes, which 3D prints housing from recycled plastic, was recently contracted by ReInhabit to build ten eco-friendly homes.

Researchers at the University of Virginia (UVA), meanwhile, have developed a method of 3D printing carbon-capturing buildings from living soils. Through the layer-by-layer extrusion of a novel seed-impregnated soil-based ‘ink,’ the UVA team’s approach enables the creation of self-supporting structures that facilitate the growth of carbon-absorbing plants.

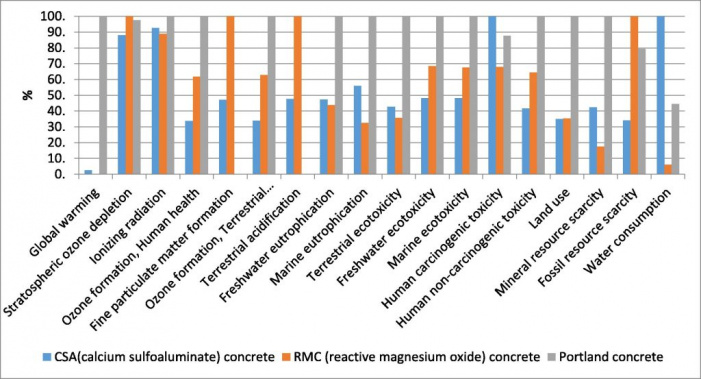

Similarly, engineers at the University of Tehran have come up with a novel concrete formulation that demonstrates how 3D printing homes improves energy efficiency. In a simulated build, the team found their magnesium oxide-based material could dramatically reduce the amount of CO2 emissions created during its construction.

Courtesy of 3D Printing Industry

Your Comment :